Factories that have been in operation for many years often experience system degradation, lack of dust treatment systems, cooling systems, and other objective reasons that cause the working environment to fail to meet standards and requirements.

A work and production environment that meets the requirements will bring the following benefits:

- Protect the safety and health of workers.

- Ensure compliance with environmental and occupational safety regulations (Ministry of Health Circular, Vietnamese Standards, etc.).

- Meet customer requirements, enhancing the company’s image.

- Enterprises exporting goods abroad must meet international standards (ISO, etc.) and the regulations of the importing country. Among these is the international standard for environmental management systems – ISO 14001. A prerequisite for a company to achieve ISO 14001 certification is full compliance with environmental protection laws.

We provide solutions for factory building systems and dust treatment systems:

- Cooling System (Cooling Pad)

Classification: Negative pressure cooling system, positive pressure cooling system

Structure: Fan, wet cooling pad frame, air duct system

Cooling principle: Hot air from outside the factory passes through the water-soaked cooling pad, lowering its temperature. The cooler air then enters to cool the space inside the factory.In large factory spaces, long-bladed fans are installed to increase air circulation and reduce humidity. The fans have a diameter of 4-7 meters.

Typical Project

Positive Pressure Cooling System Project for a Garment Factory Compliant with Circular 26.2016 by the Ministry of Health

The project ensures that the factory’s temperature is kept at ≤ 32°C and humidity at ≤ 80%

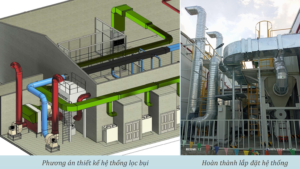

2. Dust Treatment System

Dust treatment systems are very common in factories, and the main types of dust treatment systems include:

- Cyclone dust filtration system.

- Wet dust filtration system.

- Absorption dust filtration system.

- Bag filter dust system.

- Electrostatic dust filtration system.

Types of Dust: There are 3 common types of dust in the working environment:

- Total dust: Dust with a diameter of less than 100 micrometers.

- Respirable dust: Dust with a diameter of less than 5 micrometers.

- Fine dust (PM 2.5): Dust with a diameter of less than 2.5 micrometers.

Basic Structure: Includes a suction fan system, dust suction ducts, and a dust filtration system.

Notes:

- Design the suction velocity at the suction mouth and the air velocity in the duct to match the size of the dust to ensure effective dust collection and prevent dust from settling in the ducts.

- Select a suitable dust filtration system based on the type of dust being treated.

Tiếng Việt

Tiếng Việt